No.of segment bores:11

Suitable fof capsule:00#-5#

Output:1500Capsules/min

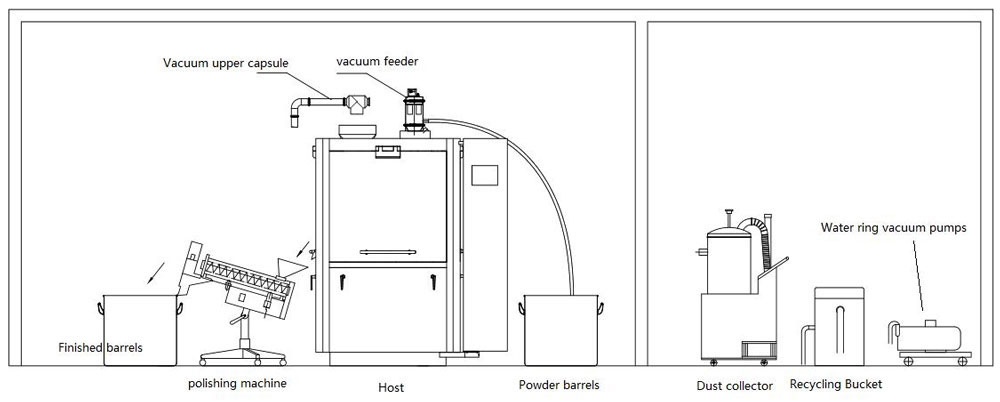

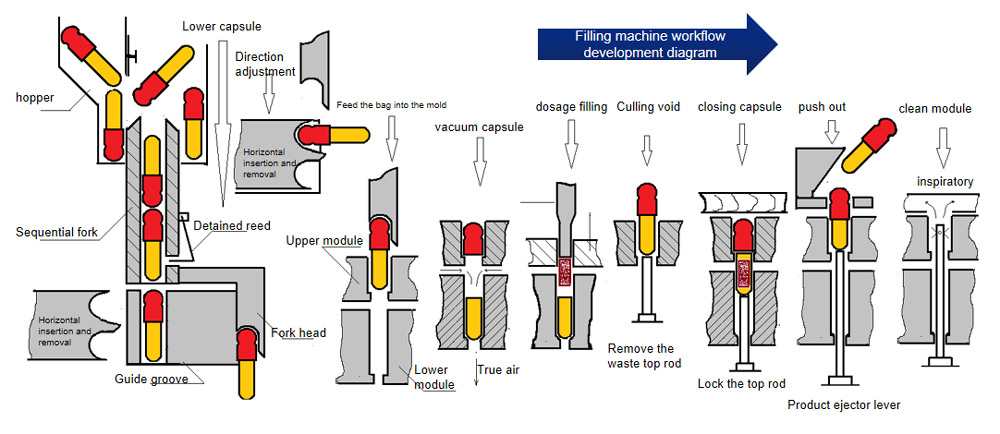

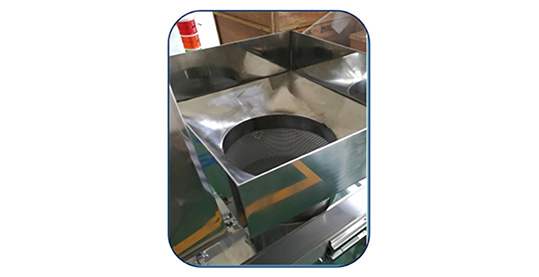

The whole machine adopts intermittent rotary mechanism and filling in a quantitative manner. It is suitable for filling powder and granule of 00#-5# capsules, and can be equipped with automatic capsule feeding machine, vacuum loading machine, gold inspection machine, polishing machine, elevator and other auxiliary equipment.

|

Output |

1500 Capsules/min |

|

No.of segment bores |

11 |

|

Suitable fof capsule |

00#-5# |

|

Total power |

8Kw(Standard configuration) |

|

Overall weight |

1400Kgs |

|

Overall diemensions |

1230mm×1175(+382)mm×1955mm |

|

Noise |

≤75DB(A) |

|

Pressure |

0.4 ~ 0.7Mpa |

|

Air consumption |

≤6m³ |

|

Vacuum |

-0.03 ~ -0.06Mpa |

|

Filling error |

±2.5%~±5% |

Hand feed

Lifter feeder (option)

Vacuum feeder (option)

Hand capsule

Automatic bag feeder (optional)

Capsule polishing machine (optional)

Sorting capsule polisher (optional)

Vertical capsule polishing machine (optional)

Metal Detector (optional)

Industrial vacuum cleaner

No. of station:15/17/20

Max.tablet diameter:25/16/13mm

No. of station:26/32/40

Max.tablet diameter:25/16/13mm

No. of station:45/55/75

Max.tablet diameter:25/16/13mm

Analysis

Consultation

Solution proposal

Quote

GET A QUOTE