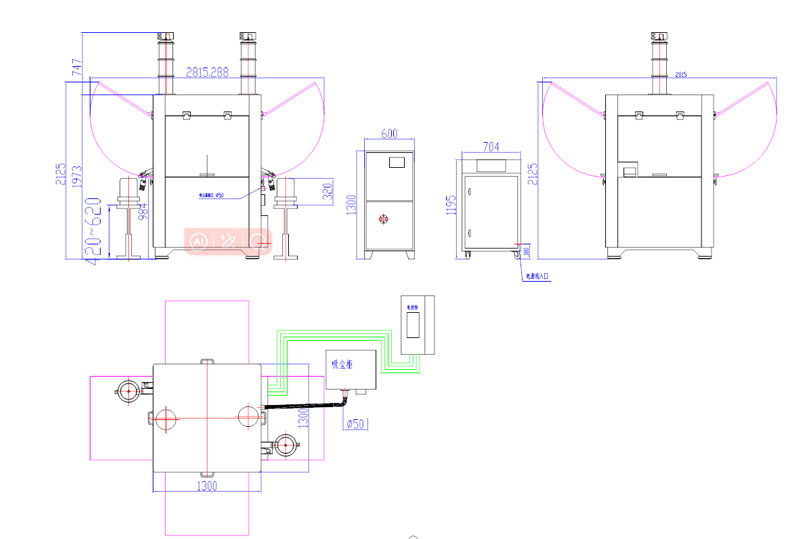

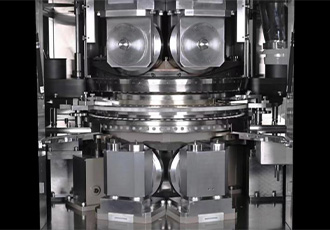

No. of station:83/65/51

Max.tablet diameter:13/16/25mm

Caoacuty:710000/560000/440000 tablets/h

The lower part of the machine is sealed by four stainless steel doors with porous material inside, and contains various driving devices to ensure safety and reduce noise. The process of tablet pressing is completed by five steps: filling, measuring, pre-pressing, main pressing and tablet drawing. The operation of the tablet press is completely controlled by the touch screen on the electric control cabinet.

|

Model |

83 |

65 |

51 |

|

No. of station |

83 |

65 |

51 |

|

Caoacuty(tablets/h) MAX OR MIN |

710000 160000 |

560000 120000 |

440000 98000 |

|

Rotation speed(rpm) |

16-72 |

16-72 |

16-72 |

|

Max.tablet diameter |

13 |

16 |

25 |

|

Main pressure |

100KN |

100KN |

100KN |

|

Pre-pressure |

100KN |

100KN |

100KN |

|

Max.filling depth |

16mm |

16mm |

20mm |

|

Maximum tablet thickness mm |

8.5 |

8.5 |

8.5 |

|

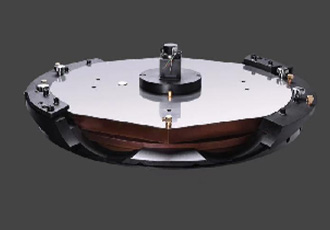

Pitch circle diameter mm |

720 |

720 |

720 |

|

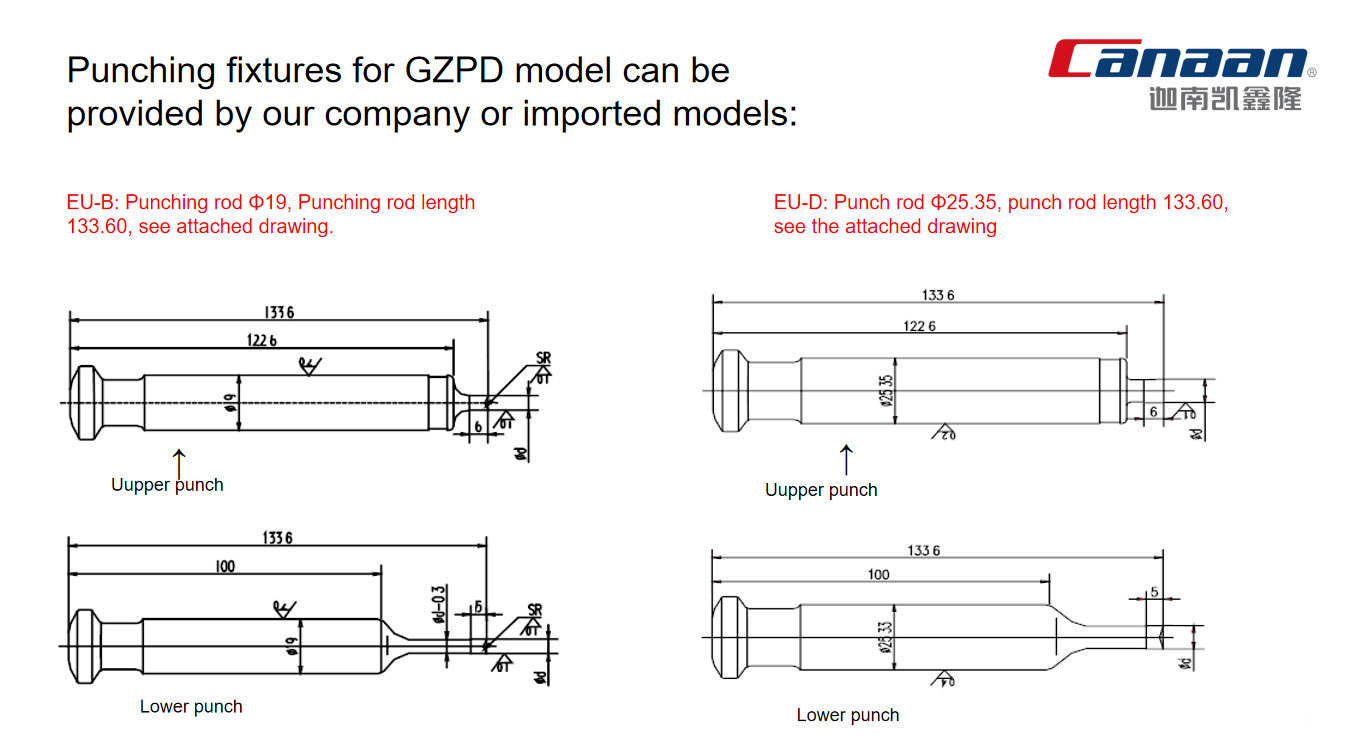

Shank diameter mm |

19 |

19 |

25.35 |

|

Middie height |

22.22 |

22.22 |

23.8 |

|

Can press shaped pieces |

YES |

YES |

YES |

|

Net weight kgs |

5000 |

5000 |

5000 |

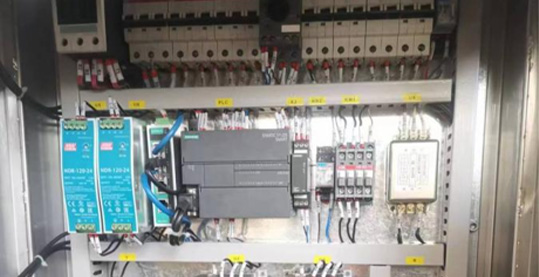

B&R PCC control systems and operating systems

No. of station:15/17/20

Max.tablet diameter:25/16/13mm

No. of station:26/32/40

Max.tablet diameter:25/16/13mm

No. of station:45/55/75

Max.tablet diameter:25/16/13mm

Analysis

Consultation

Solution proposal

Quote

GET A QUOTE