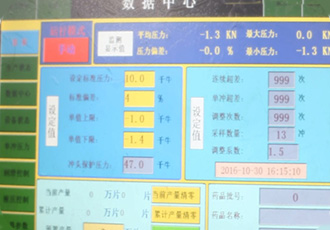

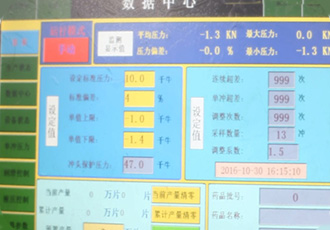

Automatic Weight Adjustment

After the production parameters are set, the system can automatically adjust the increase and decrease of the material according to the set filling amount, so as to minimize the difference in the amount of tablets.

Automatic Function of Hydraulic System

The user can set the upper and lower limits of the hydraulic system, and the computer automatically stabilizes the hydraulic pressure between the set values.

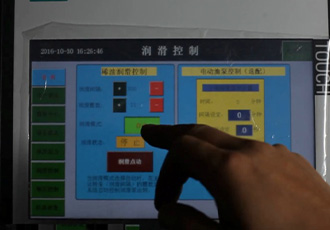

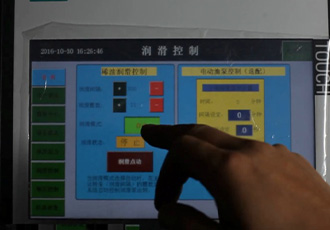

Lubrication System Automatic Function

The system controls the lubrication pump according to the lubrication time and interval parameters, and users can adjust the parameters according to actual needs.

Scrap System

The system can be used for single scrap (custom) and batch scrap. Single piece scrap to achieve a single unqualified tablet blowing into the waste channel; The channel switching solenoid valve automatically transfers to the waste channel, and the drugs are eliminated in batches.

Remove Waste Solenoid Valve

The system can be used for single scrap (custom) and batch scrap. Single piece scrap to achieve a single unqualified tablet blowing into the waste channel; The channel switching solenoid valve automatically transfers to the waste channel, and the drugs are eliminated in batches.

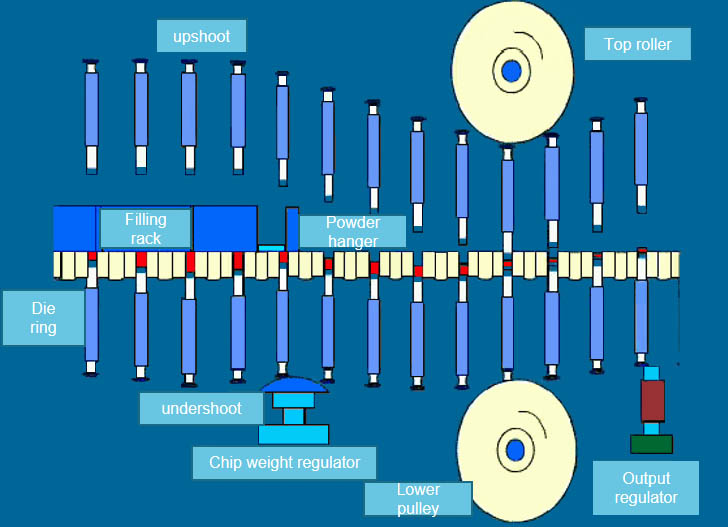

Principal Pressure

Main pressure, prepressure twice forming, large pressure wheel, five-column frame structure, so that the machine has a long pressure time, stable work and load-bearing load without deformation ability. Ensure piece weight accuracy and hardness while maintaining smooth operation and low noise.

Preloading

Main pressure, prepressure twice forming, large pressure wheel, five-column frame structure, so that the machine has a long pressure time, stable work and load-bearing load without deformation ability. Ensure piece weight accuracy and hardness while maintaining smooth operation and low noise.

Forced Feeding System

The feeder is easy to disassemble and assemble, easy to clean. High-precision double impeller forced feeding mechanism, with two agitators to force the material into each die hole, so that the difference between the weight of the sheet is smaller, to solve the ordinary sheet press free blanking insufficient filling, working disk dust and cross pollution problems.

High Precision Bearings

Adopting high-precision bearings, smooth transmission, long life and low noise.

High-Precision Guide Rails And Press Wheels

Adopting high-precision guide rails and press wheels; wear-resistant, with good consistency and interchangeability.

High Precision Punching Plate Combination

Adopting the highest domestic coordinate grinder and other equipments to ensure the dimensional accuracy, positional accuracy and roughness requirements of punching, which makes the work of replacing punching dies easier, greatly reduces labor intensity and improves labor efficiency;

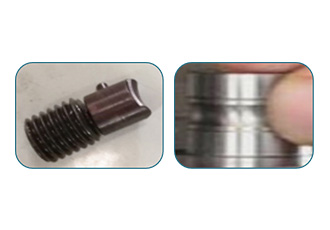

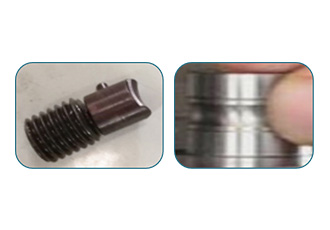

Convex-Concave Center Mold Locking Structure

The contact surface of the top wire of the center punch plate is convex-concave, and the convex-concave surface of the top wire and the ring groove of the center die make a horizontal fit to tighten (face-to-face contact), which ensures that the center die won't be taken out of the tableting machine for a long period of time, which is extremely high in safety and lowest in risk.