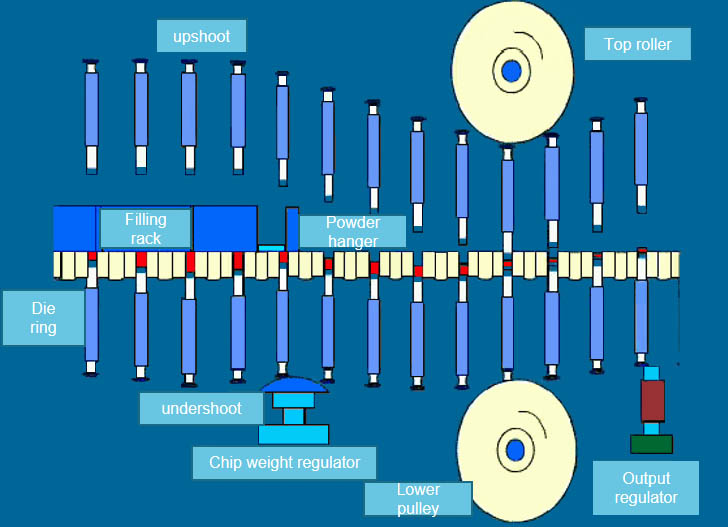

Stepped Triple Impeller Feeder

The design of large area overfilling, lengthening dosing section and high-precision forced-feeding system make the difference control of slice weight more accurate;

The double step design buffered the impact force of the material falling, effectively used the feeding area, avoided the parallel feeding blind area, no feeding dead Angle;

Three-Stage Transmission

The three-stage transmission system (pulley combination, turbine pair, gear pair), the main shaft does not rotate and the frame is firmly connected, and the main motor power directly drives the impact and rotation;

The punch plate rotates around the fixed spindle, making the punch plate surface runout and warp runout tend to zero, which greatly improves the rotating smoothness.

Principal Pressure

Main pressure, prepressure twice forming, large pressure wheel, five-column frame structure, so that the machine has a long pressure time, stable work and load-bearing load without deformation ability. Ensure piece weight accuracy and hardness while maintaining smooth operation and low noise.

Preloading

Main pressure, prepressure twice forming, large pressure wheel, five-column frame structure, so that the machine has a long pressure time, stable work and load-bearing load without deformation ability. Ensure piece weight accuracy and hardness while maintaining smooth operation and low noise.

Stable Hydraulic System

The hydraulic pump station and accumulator form a static pressure preservation system, which realizes the elastic support and overload protection of the pre-pressing wheel and the main pressing wheel, and ensures the smoothness and low noise of the pressing process.

Automatic Piece Weight Adjustment

After the production parameters are set, the system can automatically make adjustments to increase and decrease the amount of material according to the set filling amount in order to minimize the amount of difference in the tablets.

Hydraulic System Automatic Function

The user is able to set the upper and lower limits of the hydraulic system and the computer automatically stabilizes the hydraulic pressure between the set values.

Three Precise And Automatic Lubrication Systems

Fully automatic centralized lubrication system with high-precision central lubrication pump and quantitative distribution valve not only ensures the full lubrication of punching dies, guide rails, pressure wheels and other positions, but also solves the problem of oil contamination of tablets.

Three Precise & Automatic Lubrication Systems

Intermittent thin oil lubrication system: timed quantitative, open pipeline lubrication up and down stroke rod, effectively reduce the probability of lubricating oil contact with drugs, that is, reduce the possibility of drug pollution;

Scrap System

The system can carry out delayed reject function. When the equipment starts and stops, the channel switching solenoid valve automatically switches to the waste channel and rejects the waste pieces automatically.

Scrap Solenoid Valve

The system can carry out delayed reject function. When the equipment starts and stops, the channel switching solenoid valve automatically switches to the waste channel and rejects the waste pieces automatically.

High-Precision Worm Gear

Professional manufacturers guarantee the transmission worm gear pair to 6 levels of accuracy.

High-precision Worm Gear

Professional manufacturers guarantee the transmission worm gear pair to 6 levels of accuracy.

High Precision Gear Pair

Special process is adopted to ensure that the transmission gear pair reaches 6 level accuracy, strong bearing capacity, long life and low noise.

High Precision Punching Plate

Advanced processing equipment and reasonable process methods ensure the high precision and high quality of the core components.

High Precision Bearings

Adopting high-precision bearings, smooth transmission, long life and low noise.

High-Precision Guide Rails & Press Wheels

Adopting high-precision guide rails and press wheels; wear-resistant, with good consistency and interchangeability.

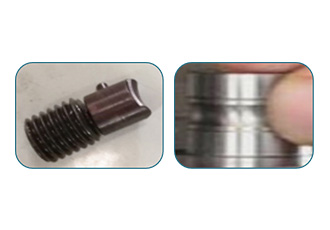

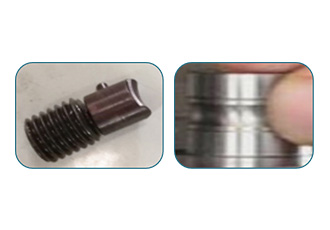

Convex-Concave Center Mold Locking Structure

The contact surface of the top wire of the center punch plate is convex-concave, and the convex-concave surface of the top wire and the ring groove of the center die make a horizontal fit to tighten (face-to-face contact), which ensures that the center die won't be taken out of the tableting machine for a long period of time, which is extremely high in safety and lowest in risk.

Dual Slice Systems

Under the pressure of the main press wheel, the hardness of the tablets increases with the increase of the compression stagnation time, which can significantly improve the hardness and get better quality of the tablets, with the function of pressing double-layer tablets, and can also press ring-shaped tablets and shaped tablets.

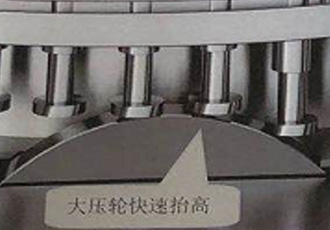

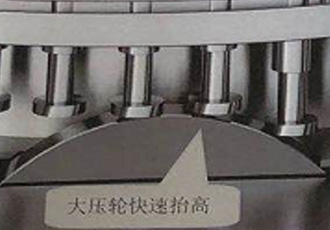

Rapid Elevation of The Large Pressurized Wheel

Capable of checking the weight of the first layer of tablets online. When the first layer of tablets is weighed, a cylinder-type pressurizing structure is used to quickly pressurize the first layer of tablets. Then the first layer of tablets is discharged by the first compression station under the punch lifting mechanism, and the weight of the first layer of tablets is detected in time.

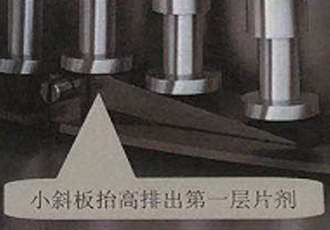

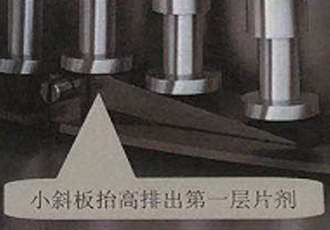

Small Inclined Plate Elevated To Discharge The First Layer of Tablets

Capable of checking the weight of the first layer of tablets online. When the first layer of tablets is weighed, a cylinder-type pressurizing structure is used to quickly pressurize the first layer of tablets. Then the first layer of tablets is discharged by the first compression station under the punch lifting mechanism, and the weight of the first layer of tablets is detected in time.

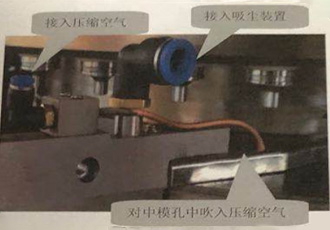

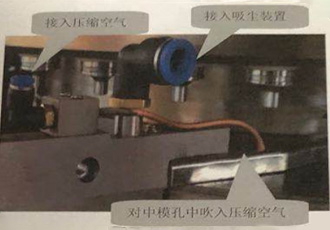

Dual Layer Chip System

It has the function of cleaning the middle mold to ensure that the double-layer tablets will not be mixed and the boundary is not clear. After the initial compression of the first layer of material, the uninterrupted air blows up the excess dust in the middle mold, which is sucked away by the dust-absorbing device through the dust-absorbing channel to ensure that there is no mixing of double-layer tablets and the boundary is clear after pressing.

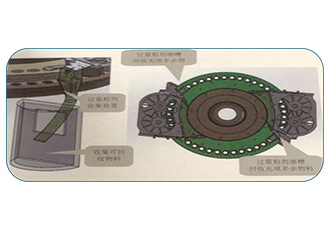

Double Layer Chip Material Recycling System

The double layer sheet press has a material recycling feature. Excess material from the first layer is removed from the mold cavity and sent to the left collector. The remaining material from the second layer is sent to the right collector (no material circulation between the two layers). This completes the function of recycling the double-layer material without mixing.

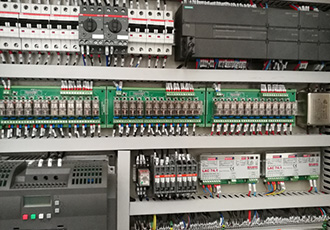

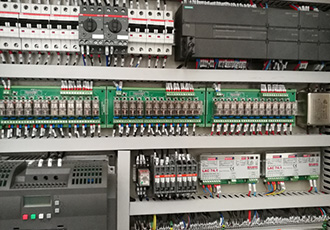

Reliable Electrical System

Each functional parameter is automatically controlled by the programmable controller, the main electronic control components adopt imported brands, international wiring, easy to repair and maintenance, advanced control principle, reliable imported devices, to ensure the precise realization of the program control and chain protection function.