Centralized Lubrication System

Dry oil lubrication system, thin oil lubrication system and circulating lubrication system provide enough lubricant to each lubrication part through automatic control to ensure the safe operation of the machine.

Scrap System

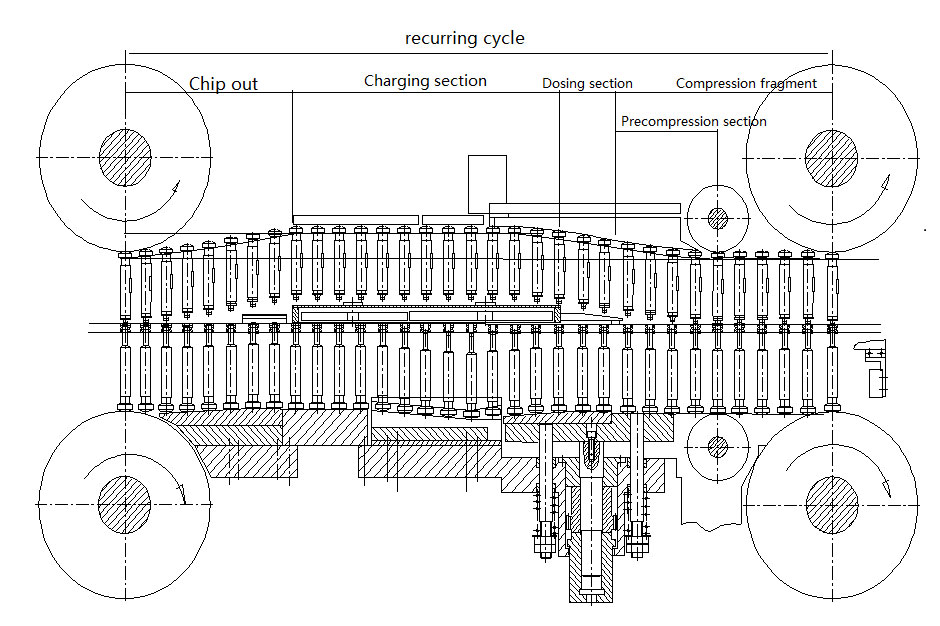

The system has two channels for batch eliminations. The operating state of the two channels is controlled by a transfer solenoid valve mounted on the outlet slot. When the machine starts working, the scrap channel is opened. Once the required punching speed is reached, the waste channel is automatically closed according to the setting, and the qualified chip channel is opened. In the case of shutdown or emergency stop, the qualified film channel is closed immediately, and the waste film channel is opened at the same time.

Principal Pressure

Main pressure, prepressure twice forming, large pressure wheel, five-column frame structure, so that the machine has a long pressure time, stable work and load-bearing load without deformation ability. Ensure piece weight accuracy and hardness while maintaining smooth operation and low noise.

Preloading

Main pressure, prepressure twice forming, large pressure wheel, five-column frame structure, so that the machine has a long pressure time, stable work and load-bearing load without deformation ability. Ensure piece weight accuracy and hardness while maintaining smooth operation and low noise.

Forced Feeding System

The feeder is easy to disassemble and assemble, easy to clean. High-precision impeller force-feeding mechanism, with the agitator to force the material into each die hole, so that the difference in the weight of the sheet is smaller, the feeder feeder feeder groove is equipped with two receiving scraper, used to recycle the material on the surface of the middle punch tray into the feeder. The problems of insufficient filling of free blanking, excessive dust of working plate and cross contamination of ordinary sheet press are solved.

High Precision Bearings

Adopting high-precision bearings, smooth transmission, long life and low noise.

High-Precision Guide Rails & Press Wheels

Adopting high-precision guide rails and press wheels; wear-resistant, with good consistency and interchangeability.

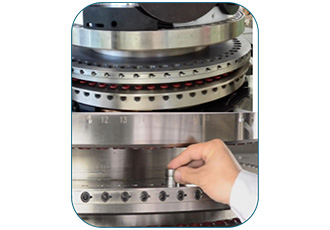

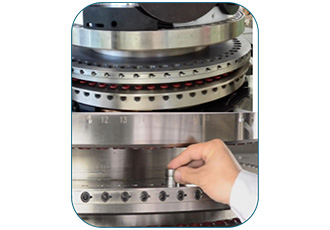

High Precision Punching Plate Combination

The company's middle die holes in the boring machine cutting, and then each hole grinding, at the same time with the coordinate detection equipment for hole detection, to ensure the finish and accuracy of the hole. The processing cost is much higher. The punch plate is the most core workpiece of the tablet press, and its accuracy can fully represent the overall accuracy of the high-speed tablet press.

Manual Punch Replacement

Remove and assemble the mold by hand without borrowing any tools. The design and development ensure that the medium die hole of the plate of the high speed tablet press will not be deformed for a long time.

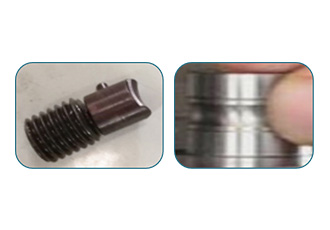

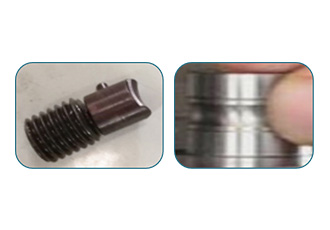

Convex-Concave Center Mold Locking Structure

The contact surface of the top wire of the center punch plate is convex-concave, and the convex-concave surface of the top wire and the ring groove of the center die make a horizontal fit to tighten (face-to-face contact), which ensures that the center die won't be taken out of the tableting machine for a long period of time, which is extremely high in safety and lowest in risk.